Hot water is treated as a separate topic because it involves the consumption of water, gas, and electricity. In our house, the hot water is distributed through two nearly identical systems – one for the upstairs and another for the downstairs. The two hot water heaters are located in a utility room in the southeast corner of the house, while the main showers are located diagonally opposite in the northwest corner of the house. The pipes are 1/2 inch uninsulated copper and buried in the cement floors and walls.

During a remodel, two dedicated return lines, also 1/2 inch uninsulated copper were added to both upstairs and downstairs systems. These lines are used with small pumps to recirculate the hot water from the showers back to the hot water heaters. The return lines permit the showers to produce hot water within a few seconds of turn on rather than 3 to 4 minutes. There are a variety of ways to control the recirculation system which will be discussed below.

The water heaters were previously two Rheem 20 gallon tank type units that were about 10 years old when I began measuring the performance of the hot water system. Tank type heaters are the type most commonly seen in Mexico, but they are increasingly being replaced with tankless units. The Rheem heaters were beginning to act up, so they were replaced with two tankless Bosch heaters rated for 17 liters/minute delivery. This size heater is sufficient for at least two showers running simultaneously. One of the advantages of a tankless heater is that it produces a constant temperature of hot water as long as it does not exceed the rated delivery. Ours were set for 49 deg C (120 deg F) which is recommended as the maximum to avoid scalding.

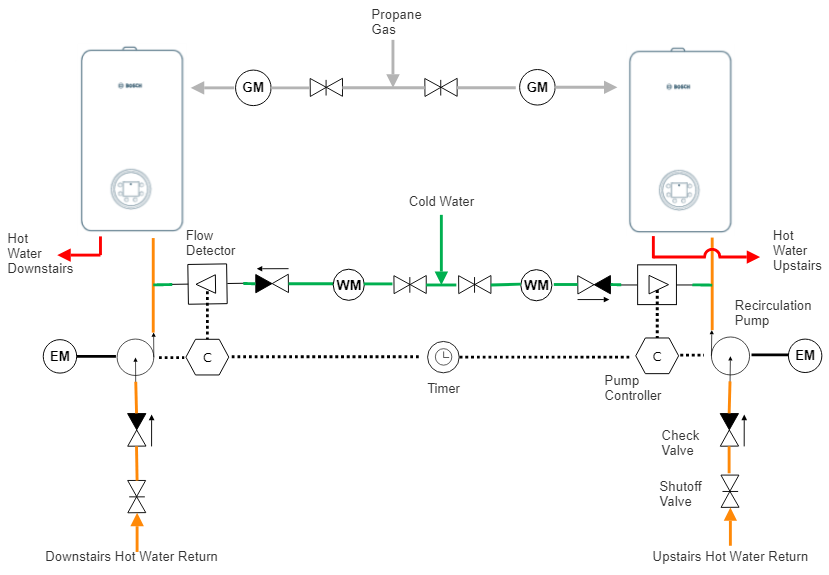

When the new heaters were installed, the plumbing was done in a way that allowed for easy removal and insertion of the flow sensors, check valves, and recirculation pumps used in the recirculation system and for the gas meter (GM), water meter (WM) and electric meters (EM) that are part of the EKM Metering system already discussed. (See Propane Measurements and Water Measurements).

The above diagram shows propane gas lines with shutoff valves then gas meters connecting to the Bosch heaters. Actually, I have only one meter, but it can be connected inline to either the upstairs or downstairs heater.

Similarly the cold water divides through shutoff valves, and then passes through water meters, check valves and flow sensors to the two heaters. Again, I have only one water meter, but it can be placed ahead of either heater.

Return hot water passes through a shutoff valve, a check valve and a recirculation pump before it is combined with the cold water to enter the hot water heater. The pumps may be controlled from a timer, or flow sensors that energize the pumps for about three minutes after sensing a demand for hot water, or they can be manually set on or off. The electric meters shown measure the power required by the pumps. There are two of these.

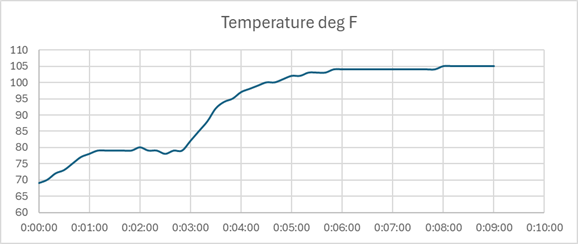

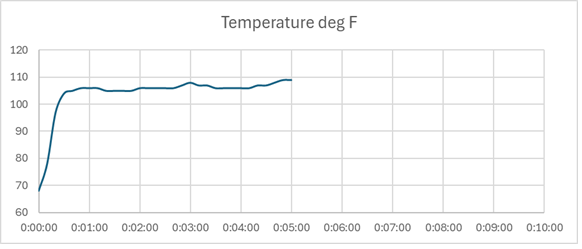

To evaluate the different modes of operation, the upstairs system was monitored during a “standard shower” of five minutes duration. The five minute shower began when the water temperature at the shower reached 95 degrees F, and only the hot water was turned on. This resulted in the shower temperature reaching 110 degrees or so, which would normally be moderated by mixing it with cold water, but that was not done during the tests. For comparison purposes, only one shower per day was assumed, and no other use was made of the hot water during the day. The water temperature at the shower head was measured by a temperature gauge recorded on a video. The data at ten second intervals was then plotted.

Standard Shower without Recirculation

This test was performed in March when the normal daytime temperature is about 70 deg F. The water temperature flow starts at about 68 deg F. After a minute it reached 80 deg F, then between three and four minutes it increased to 95 deg. This is when the five minute shower began. The test ended at nine minutes.

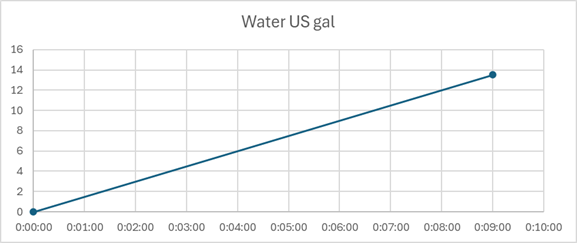

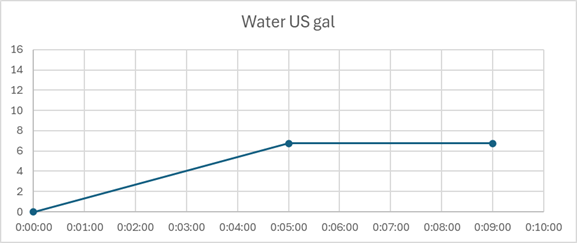

The water flowed at a constant rate between zero and nine minutes with the total flow being 13.5 US gallons. 44% of this was wasted waiting for the temperature to reach 95 degrees.

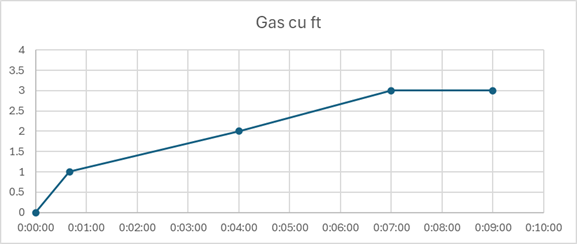

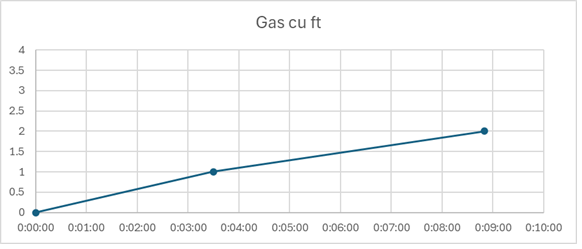

The readout resolution of the gas meter is only one cu ft, so the data is not as refined as might be desired. Overall, a total of three cu ft of gas was used. However the first two cu ft were used to heat the cement surrounding the gas pipes from the water heater to the shower head, then another one cu ft was used to heat the water used for the five minute shower.

In summary, this shower required a wait time of four4 minutes, and consumed 13.5 gallons of water, no electricity and three cubic feet of gas. Using the average conversion factor discussed in Propane Calculations , this amounts to about 0.3 liters of liquid propane.

Standard Shower with Demand Recirculation

The same data may be used to calculate the performance and consumption of water, gas, etc. with a demand recirculation system. The demand flow is triggered at time zero but no water flows for the first 4 minutes while the recirculating pump heats up the water in the pipes (and the surrounding cement floor and walls). Gas usage is the same. The recirculation pump requires 74 watts over the entire 9 minute interval plus an additional 4 minutes before it turns off. The electricity required by the pump is just 74 watts x 13/60 hours x .001 kWh per watt hour. In summary then, wait time is still 4 minutes, water consumption is 7.5 gallons, gas used is 3 cu ft (0.3 liters liquid) and electricity consumed is 0.016 kWh.

Standard Shower with Timer Controlled Recirculation

For this test, the recirculation system was turned on for several hours to preheat the water and its surroundings. The gas required to maintain the recirculated flow was found to be one cu ft every 18 minutes after the temperature stabilized and before the shower was turned on. After the shower was turned on the temperature was recorded along with the water, gas and electricity consumption for five minutes because the temperature reached 95 degrees within a few seconds of turn on.

Total water use is six US gallons and none is wasted. Electricity, if the pump is kept running continuously is 74 watts x 24 hours x .001 kWh per watt hour or 1.78 kWh per day. Gas consumption is 1/18 cu ft per minute x 60 min/hr x 24 hr/day = 80 cu ft per day to recirculate the water. An additional one cu ft of gas is used to supply the hot water for a five minute shower.

The above arithmetic can be used to calculate the usage if the timer is set for a shorter time interval per day. For example, if it is set to recirculate for 1 hour, the water use is still six gallons, electricity is 1.78/24 = .074 kWh and gas is 80/24 + 1 = 4.33 cu ft.

Cost Comparison

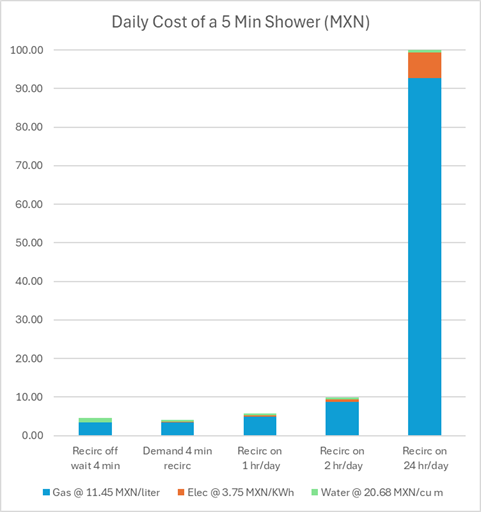

The above utility usage can be combined using the current rates for water, electricity and gas to compare the total cost of the various recirculation modes.

For gas: 11.45 MXN per liter

For water: 20.68 MXN per cubic meter

For electricity: 3.75 MXN per kWh

The first thing to note is that the cost of gas dominates the total cost for any of these scenarios.

The second is that the cost for the convenience of never waiting for hot water is pretty high. It is 100 pesos per day (US$5) vs 4.49 pesos (US$0.22) for no recirculation and a four minute wait.

Using the demand system controller reduces the cost to 4.08 pesos (US$0.20), an almost insignificant savings of 41 pesos (US$0.02). And you still have to wait four minutes.

With the timer, the savings depends on how well you can predict and stay with your schedule. Narrowing down the time for a shower to a 1 hour schedule costs 5.77 pesos (US$0.29) while a two hour time slot costs 9.86 pesos (US$0.49) per day. But whatever the time interval, there is no waiting for hot water during this time.

Survival Operation

During a survival situation, the recirculation system should be turned off to save gas.