Leaks can be detected using a spray bottle of soapy water or one of the electronic leak detectors available that use a metal oxide semiconductor (MOS) sensor. The latter are available with digital readouts that show parts per million gas concentration or with simple LEDs which light when a threshold is exceeded. The LED versions are much less expensive and more than adequate, especially since the LCD readout on the digital displays are not very visible under daylight conditions. Both the LED and LCD meters sound a buzzer when propane is detected and are very convenient to use compared to the soapy water.

Gas lines are normally run outside the house, but not entirely. Sometimes they go under the floor or in the walls where they cannot be tested using any of the leak detectors. In that case, there is another method that is very sensitive.

A pressure gauge (manometer) can be connected to the gas line, then the line closed using a valve which should be located near the pressure regulator. If all other appliances are turned off (including the pilots on water heaters, fire places, etc.) the pressure should hold constant. A manometer with digital readout is shown below. It is designed ONLY for the low pressure gas lines that connect directly to the appliances. These are all rated for 10 to 12 inH2O (inches water column). The manometer comes with a 1/8 inch plastic tube designed for a barb fitting. To connect it to one of the flexible gas lines used to connect to an appliance, use a 1/8 inch barb to 1/4 inch NPT male adapter and a 1/4 inch NPT female to 3/8 inch flare adapter. Both of these are available on Amazon, but not easy to locate in Mexico.

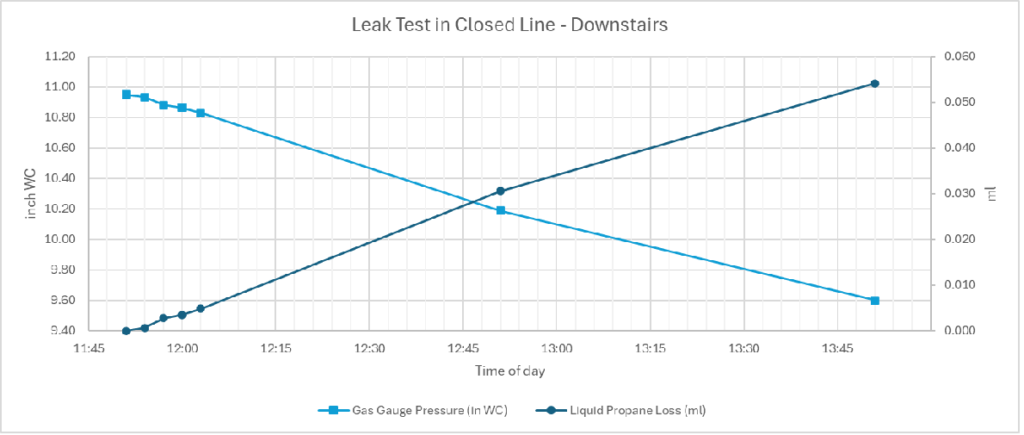

The pressure reading versus time was recorded for one of our low pressure lines. The initial reading was 10.95 and three minutes later it was 10.93 inH2O. This difference would not be detectable using a standard analog pressure gauge. Three minutes is the minimum test time required by US building codes for this test. But the pressure continued to drop very slowly as shown by the plot below. After 2 hours, it had declined to 9.60 inH2O. The light blue line shows the pressure.

To relate this to actual propane lost, the gas volume, pressure and temperature can be used to find the mass of propane lost which in turn can be converted to liquid propane lost. See the page Propane Calculations. The result is the dark curve which shows the liquid loss in milliliters. This is very little. The upper right data point is just above 0.05 ml which is 1 drop.

This is not to make light of a gas leak. But it would not be worth tearing the walls apart to find one this small, and it certainly is insignificant in terms of affecting the gas storage needed for survival.